Steel Fibre

Construction steel fibers are small, discrete pieces of steel that are used to reinforce concrete and other composite materials. They enhance the mechanical properties of the material, such as its tensile strength, toughness, and resistance to cracking.

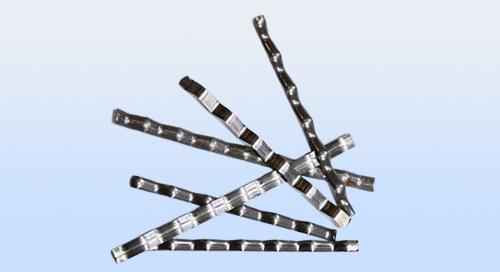

Crimped Fibers

- Have a wavy or crimped shape to enhance bonding with the concrete.

- Offer a balance between cost and performance.

Hooked-End Fibers

- These fibers have hooks at both ends to improve their bonding with the concrete matrix.

- Commonly used in applications requiring high levels of reinforcement.

Properties, Applications and Advantages

Increased Tensile Strength: Steel fibers add tensile strength to concrete, which inherently has low tensile strength.

Helps in reducing the occurrence of cracks.

Enhanced Toughness: Improves the toughness and ductility of concrete.

Provides better resistance to impact and dynamic loads.

Crack Control: Distributes stresses more evenly and controls crack propagation.

Helps in maintaining structural integrity even after the formation of cracks.

Durability: Improves the durability of concrete by enhancing its resistance to wear, abrasion, and chemical attacks.

Flexural Strength: Enhances the flexural strength, allowing the concrete to withstand bending forces more effectively.

Industrial Floors:

strong> Used in industrial flooring to provide high resistance to impact, abrasion, and heavy loads. Ensures longevity and reduces maintenance costs.

Tunnels and Underground Structures:

Enhances the structural integrity of tunnels and other underground constructions. Provides better resistance to ground movements and seismic activities.

Bridges and Pavements:

Used in bridge decks and pavements to enhance load-carrying capacity and durability. Reduces the occurrence of cracks and spalling.

Precast Concrete Products:

Commonly used in precast products like pipes, manholes, and panels to improve their structural performance. Allows for thinner sections without compromising strength.

Shotcrete:strong>

Used in shotcrete applications for slope stabilization, lining of tunnels, and repair works. Enhances the adhesion and cohesion of the shotcrete mix.

Hydraulic Structures:

Used in dams, reservoirs, and canals to improve durability and reduce maintenance. Provides resistance to erosion and cavitation.

Residential and Commercial Buildings:

Employed in the construction of foundations, slabs, and walls to improve load-bearing capacity and durability. Enhances the overall performance of structural elements.

Reduction in Reinforcement Steel:

Can reduce or eliminate the need for conventional reinforcement bars in certain applications. Simplifies the construction process and reduces labor costs.

Improved Load-Bearing Capacity:

Enhances the load-bearing capacity of concrete structures. Allows for more efficient and economical designs.

Cost-Effectiveness:

While the initial cost of steel fibers may be higher, the overall cost is often reduced due to lower labor costs and reduced need for maintenance.

Versatility:

Can be used in a wide range of applications and environments. Suitable for both new constructions and repair works.

Technical Data / Project Sheets

Check Technical Data / Project Sheets of our work.